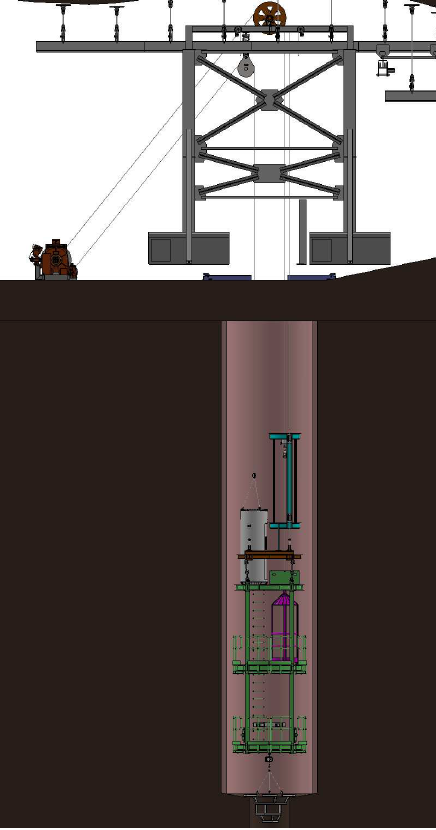

Traditionally at Fortis, our Mining Division outpaces our Engineering and Manufacturing Division for international work. With this said, recent developments have garnered our Engineering and Manufacturing Division international renown. Fortis has been contracted by a client to build a custom Galloway as well as design, and supply shotcrete buckets, material buckets, man baskets, emergency capsule, guiding crosshead as well as sheave mounting, sizing, and supply for a liner installation in a shaft for a client. The site is located Chile.

Contact Fortis for additional information on our Engineering and Fabrication capabilities

Phone 306-242-4427 or Toll-Free at 1-844-542-4427

Email info@fortiscorporation.com

Website https://www.fortiscorporation.com/engineering.aspx

General Arrangement

Shotcrete Bucket Chaired On Galloway

Guided Crosshead with Man basket

Guided Material Basket with X-head

Emergency Conveyance

Bottom level of Galloway with Shaft plug and Man Conveyance

The mining consumable, Track Pins, were developed by Fortis Mining Engineering and Manufacturing to help assist undercutters at various mine sites.

Undercutters are used to cut the floor or wall in the mine to create a pathway so the ground is able to move. The Track Pin was created for the Under Cutter to ensure that it continuously operates effectively.

The Track Pin helps reduce the maintenance on mining Undercutters. Fortis Mining Engineering and Manufacturing's Track Pin is made with an alternative type of steel to safeguard it from breaking.

For more information on custom engineering, fabrication, and manufacturing contact us.

Phone: 306-242-4427

Email: sales@fortiscorporation.com

802, 57th Street East

Saskatoon, SK S7K 5Z1

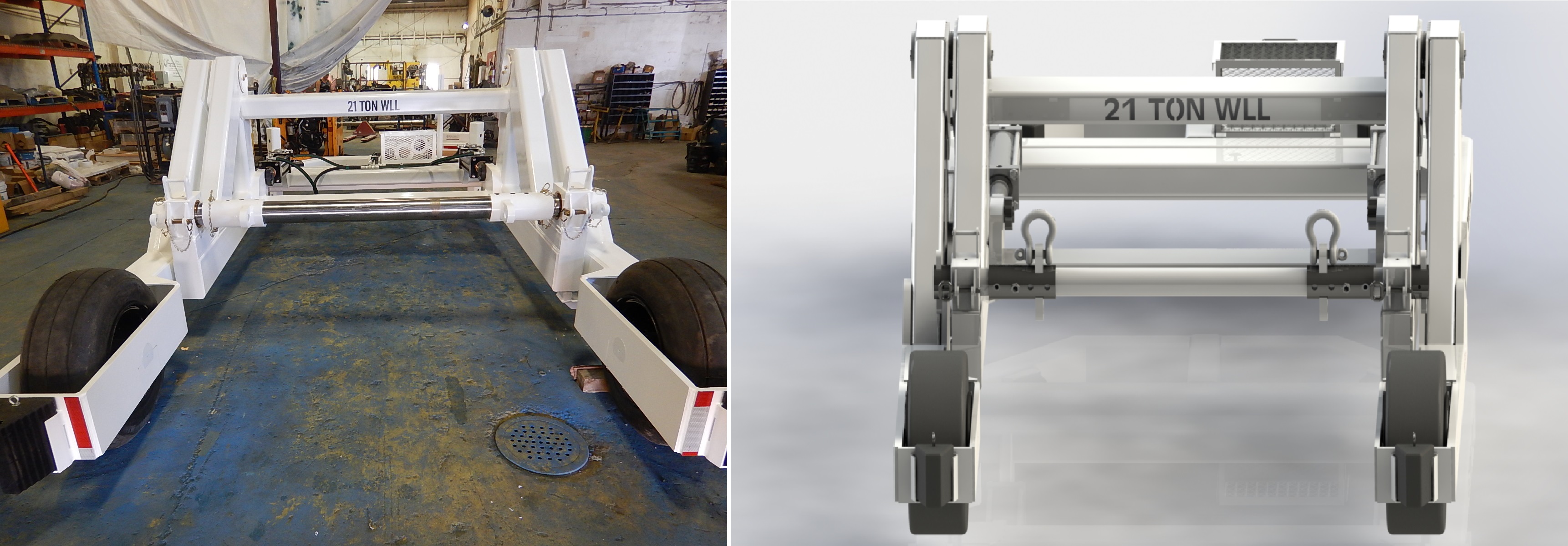

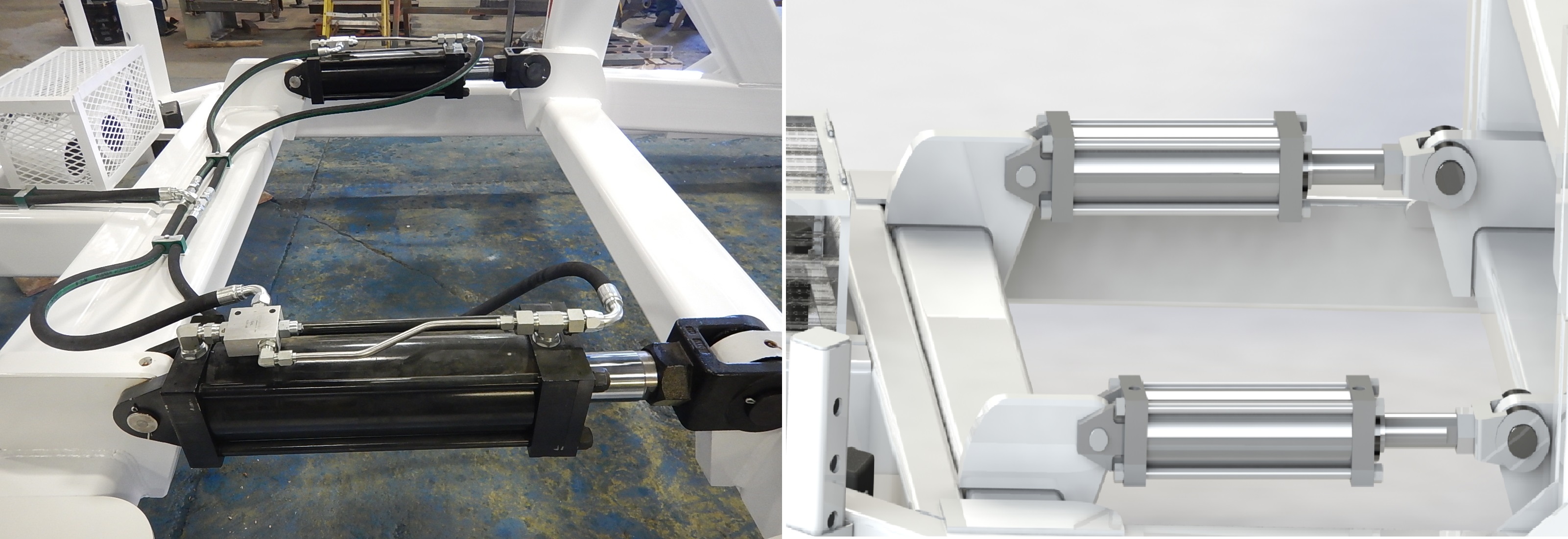

Fortis Mining Engineering and Manufacturing recently completed a job that required both engineering, manufacturing, and fabrication services. Searching for an efficient and safer alternative to transport reels, Fortis Mining Engineering and Manufacturing was tasked with creating a Reel Winder Trailer to fit specific client needs.

There are many unique specifications that the client required Fortis Mining Engineering and Manufacturing to adhere to to ensure the success of the Reel Winder Trailer.

The location that the reels were to be moved is very narrow. Therefore, the Reel Winder Trailer had to be engineered to move through this space, while still allowing for the pick up of different sizes of reels from diameter to width.

The engineered Reel Winder Trailer is narrow and capable of picking up various sizes of reels up to a maximum capacity of 21 tons using hydraulic auxiliary outlets.

Wire rope, plastic, pipe, and numerous other products that come on a reel can be transported using the Reel Winder Trailer. Fortis Mining Engineering and Manufacturing was able to successfully meet the client's specific and unique needs in order to provide a superior solution for reel transport.

For more information on custom solutions and services, please contact Fortis Mining Engineering and Manufacturing.

Phone: (306) 242-4427

Toll Free: (844) 542-2247

Email: info@fortiscorporation.com

Fortis Mining, Engineering &

Manufacturing was recently contracted by SaskPower to complete a comprehensive

Lifting Lug & Monorail Remediation project at the Shand Power Station. The project

consisted of multiple components including: 1) inspecting, load testing and

certifying existing lifting lugs and monorails within the plant to bring them

to current client and occupational health and safety standards; 2) adding or

modifying supporting structural steel to existing lifting lugs and monorails

followed by the load testing and certification of the device; and 3)

Installation of new lifting devices and monorails including all supporting

structural steel installations, load testing and certifying of the new lifting

devices. The total project consisted of

244 items including 219 Lifting Lugs and 25 Monorails. This included 18 New

Lifting Lug Installations, the inspection and testing of 184 existing lugs, the

installation of 9 new monorails, and the inspection, testing, and painting of

15 existing monorails.

As part

of the project execution, Fortis was responsible for completing all structural

detailing, providing certified shop and erection drawings, fabrication of all

structural steel, installation of all structural steel and lifting devices,

load testing of all components, and generating test reports and turnover

documentation for the client. Fortis also designed and fabricated custom sized

weld and bolt-on lifting lugs in-house for the project to suit applicable site

standards and colour coding.

To

ensure quality of products provided an Inspection Test Plan was developed to

ensure compliance to applicable standards and specifications. Fortis also

developed a comprehensive digital and physical turnover package including all

relevant company and personnel certifications, project registers, executed ITP

and check sheets, as-built/redline drawings, procedures and manuals, and all

other quality documentation compiled.

Fortis

Mining Engineering and Manufacturing has achieved and maintained ISO 9001

Quality Management, 14001 Environmental Management and OHSAS 18001 Health &

Safety Management Certifications.

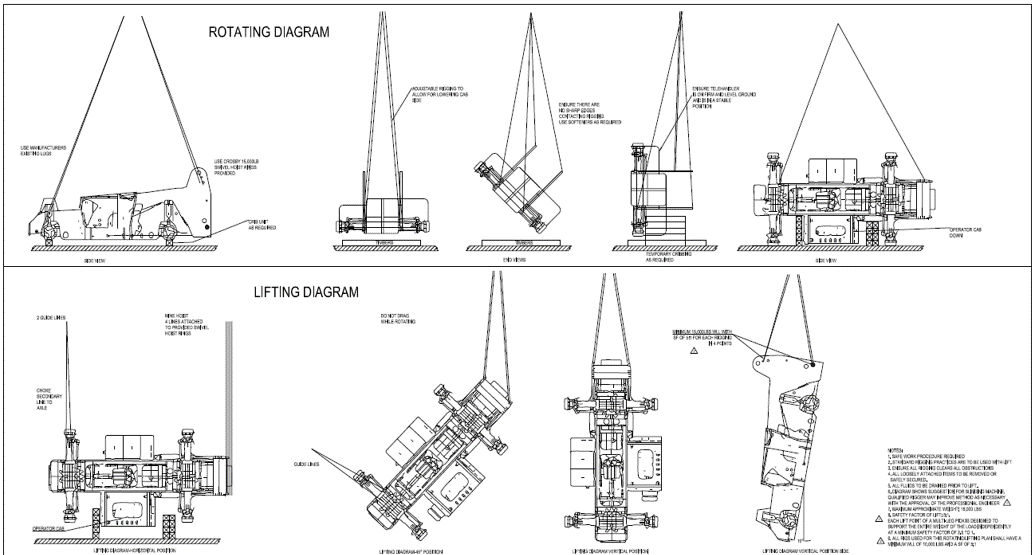

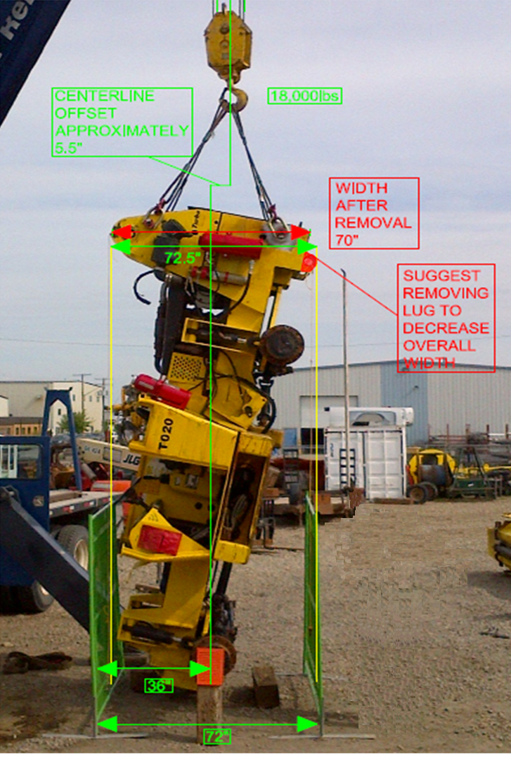

Fortis Mining Engineering and Manufacturing has an abundance of experience in providing lift studies and engineered lift plans for the Potash Mines of Saskatchewan with recent experience including development of lowering procedures with Blair Hoists and Sinking Winches.

Fortis has also developed a test lifting criteria for components which confirms that each piece of equipment hangs as per design within the individual shaft parameters which virtually eliminates rigging issues during shaft lowering.

Fortis rigging plans utilize our underground experience to maximize the capabilities of the shaft profile and hoist lifting capabilities.

Reduction in disassembly of equipment to get underground has saved client time and money.

Comprehensive lowering methodologies typically include a site specific material hoisting basket design that is compatible with the sinking arrangement if a cage is not available. This allows 'light loads' on pallets, bundles, or crates to be safely transported underground with speed and consistency.

Fortis is an industry leader in the development of critical lift plans for the mining and construction industries.