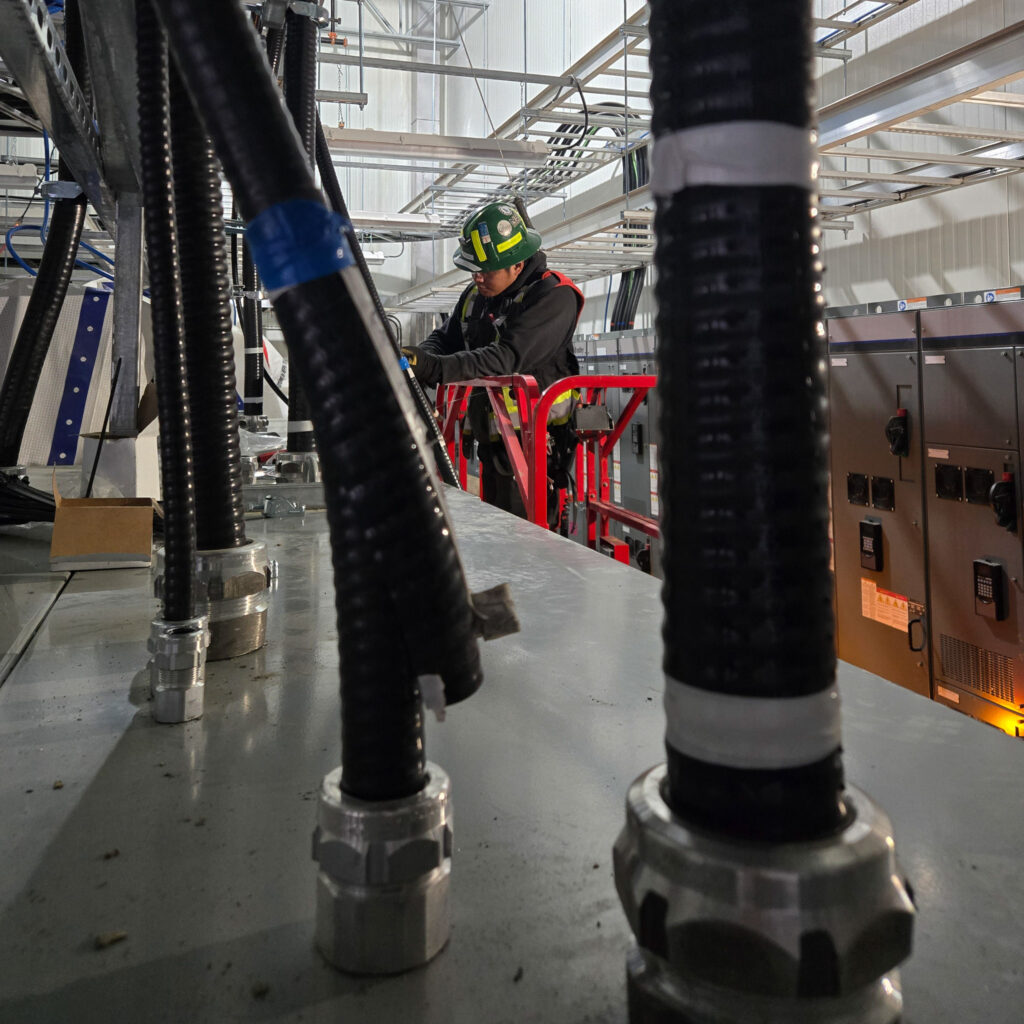

Fortis Electrical personnel have hands-on experience installing, troubleshooting, maintaining, and servicing electrical systems. Our teams’ key focuses are Quality, Safety, Efficiency, and Relationship Building. From commercial projects and maintenance to high-voltage cable work, motor control systems, and mining equipment, Fortis delivers practical, reliable electrical solutions tailored to each project’s needs.

Qualifications

- QEW (Qualified Electrical Worker)

- Licensed Red Seal

- High-Voltage Splicing/Terminating

- FSR-A (Field Safety Representative, No Restrictions, B.C)

- Master (Alberta)

- Below the Hook

- Confined Space

- Suspended Access

- First-Aid

- GMSA

- SCOT

- OH&S Supervision

- Aerial Work

Industrial/Commercial Services

- Indoor and outdoor lighting

- Typical infrastructure power distribution (receptacles, data, control and equipment)

- Site contracting

- Planning

- Permitting

- Overhead cranes

- Equipment

- Distribution

- Ventilation

- De-watering

- Troubleshooting

- Infrastructure power

- Heat trace

- VFD and PLC Install and Troubleshooting